Versatility of Variable Area Flow meters

Original article on Paper Advance

In manufacturing, the variable area flow meter, or rotameter, stands out for its simplicity, affordability, and versatility.

Variable area flow meters are used in pulp and paper manufacturing and other process industries, such as chemicals, oil and gas, mining, food and beverage production, and more. Its popularity stems from its uncomplicated design, cost efficiency, and adaptability to challenging environments.

What is a Variable Area Flow meter?

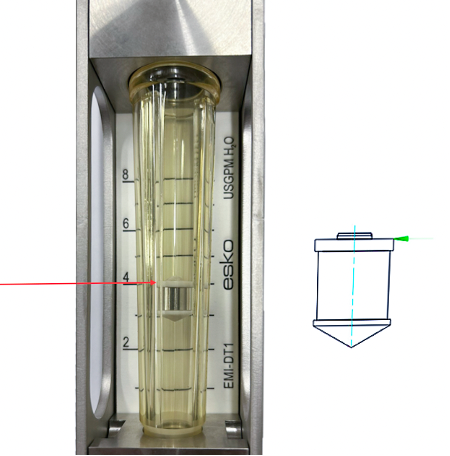

A variable area flow meter operates on a straightforward principle: as fluid flows through a tapered tube, it lifts a float. The height of the float corresponds to the flow rate, which is indicated on a calibrated scale. This ingenious yet uncomplicated design allows for accurate flow measurement of liquids and gases.

Floats inside variable area flow meters come in many different shapes, sizes, weights, and materials, specific to the application.

Guiding factors in determining the appropriate float for each application include flow media, operating temperature, and more. Read more about float materials here.

How do you accurately read the flow rate on a Variable Area Flow meter?

The important Rule of Thumb for reading the flow rate on an ESKO variable area flow meter is:

Read the flow at the highest point of the widest part of the float.

Variations in variable area flow meters

Despite its simple operating concept, variable area flow meters come in a myriad of different designs and materials.

Key Applications of a variable area flow meter in manufacturing include:

- Process Flow Monitoring

- Constantly tracking the flow rates of liquids and gases in diverse manufacturing processes, to facilitate operational consistency.

- Rotating Equipment Lubricant Flow Measurement

- Monitoring lubricant flows in rotating machinery, helping to prevent equipment failure.

- Wastewater Monitoring

- Supervising flows in wastewater treatment processes.

- Purge Applications

- Measuring and regulating small purge flows of liquids or gases.

- Dosing Applications

- Dispensing small quantities of liquids or gases.

- Chemical Injection

- Precisely managing the flow of chemicals introduced into processes is crucial for maintaining product quality and safety.

- Tank Blanketing

- Monitoring gas flow to maintain a protective layer over liquid in storage tanks, preventing contamination or evaporation.

- Boiler Control

- Regulating the flow of fuel or water to boilers, optimizing energy use and ensuring safe operation.

Benefits of Using Variable Area Flow Meters

Manufacturers opt for variable area flow meters due to several key advantages:

- Cost-Effective: Provides an economical solution compared to other types of flow meters.

- Simple Design: Facilitates easy installation and maintenance, reducing downtime.

- Visual Indication: Offers direct and immediate flow rate readings via a calibrated scale.

- Low Pressure Drop: Ensures minimal disruption to the flow system.

- Wide Application Range: Suitable for both liquids and gases, making it a flexible choice across industries.

Bottom line: Why Choose a Variable Area Flow Meter?

Variable area flow meters are popular for their simplicity and functionality. Their robust design offers reliable performance in tough environments such as high temperatures or corrosive conditions. Affordability and ease of use make them the optimal choice.

ESKO has been supplying variable area flow meters to the pulp and paper industry for over four decades. The versatility and reliability of variable area flow meters are unmatched in seal water monitoring, lubricating oil monitoring systems, chemical dosing, and more. For operators seeking a dependable, cost-effective, and easy-to-maintain flow monitoring solution, the simple but effective variable area flow meter delivers. Contact us today to see how we can help keep your processes running smoothly with tried-and-true technology.