Grease Lubrication Best Practices

Originally published on Paper Advance

How to prevent CluNKs, sQueAKs and JaMs!

Part 2 of 2 – Let’s talk about Grease

This is the second of two articles focussed on current lubrication best practices utilizing both oil and grease. For information about circulating oil monitoring systems, read the first article here.

TRIBOLOGY – Part 2 – Grease

Tribology is the science of friction, wear and lubrication in machines. The term dates back to a 1966 study by Dr. H. Peter Jost, commissioned by the British government to investigate machine damage from wear in an era when commercial production methods were rapidly developing.

PREDICTIVE & PREVENTATIVE MAINTENANCE FOR PAPER MACHINES

Oils – Many paper machines today utilize circulating oil lubrication systems to continuously monitor oil flow, condition, and temperature for optimal equipment performance.

Grease – Reliable application of grease in important points is the second key element of predictive and preventative maintenance best practices.

Applying the right GREASE

Grease is produced by adding a thickening agent (“gel-maker”) to oil to form a solid, semi-solid or semi-fluid product. The gel-maker is usually a metallic soap, which is a combination of a metal and a fatty acid, usually from animal or vegetable fat. The most common types of metal soaps in grease are calcium, sodium and lithium. For more detailed information about specialized greases including calcium, anhydrous calcium, sodium, lithium and synthetic varieties, click here.

In process machinery, the most important functions of grease are:

- LUBRICATE at different temperatures and pressures

- SEAL against dirt, dust and water

- PROTECT against corrosion

- REDUCE vibration and noise

- FUNCTION for a long time with the same consistency

OIL vs. GREASE: CONSISTENCY

The difference between oil and grease is consistency, which depends on:

- the oil and its viscosity

- the thickening agent

- the quantities of thickeners that the grease contains

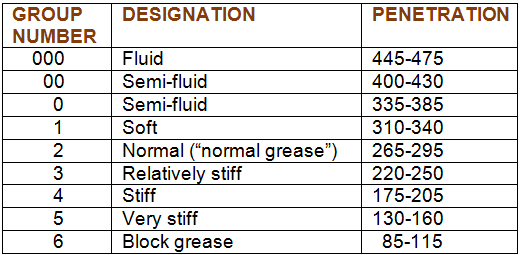

Temperature can also have an effect on consistency. Grease consistency is classified under ASTM (American Society for Testing Materials). Classification is achieved by measuring the depth to which a specially designed cone sinks during 5 seconds in the homogenized grease sample at 25°C. The consistency is expressed as penetration in 1/10mm. According to the National Lubricating Grease Institute in the USA, the consistency of grease is classified into the NLGI numbers in the table below.

GREASING SOLUTIONS TO EXTEND BEARING LIFE

In addition to managing circulating lubricating oil, grease application is another important aspect of bearing and equipment maintenance. Grease is typically applied to bearings with specialized equipment that deposits the grease between the rollers in fill percentages recommended by manufacturers, usually in the range of 20% to 40%. Paying attention to grease condition is important too. Proper storage can prevent grease from oxidizing, bleeding, and eliminate contaminants from interfering with its ability to perform as a lubricant. Over time, chemical degradation can cause the oil and thickener to separate, forming a build-up that prevents new grease from working effectively, and contributing to bearing failure. Careful application of grease (to prevent damage to seals) and keeping ports free of excess grease, debris and crusting are also advisable.

Too much or too little grease can shorten bearing life. Over-greasing can cause operating temperature to rise too quickly, especially at high speed operation. Low speed or smaller bearings however, may need more grease in the housing. For optimal bearing life, manufacturer recommendations for both the type and quantity should be followed diligently.

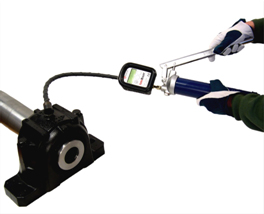

Manual Greasing – Manual greasing can be imprecise and is a frequent cause of over-greasing. Adding a light-weight digital grease meter to a manual grease gun or pump can deliver exactly the right amount of grease, keep track of how often it is applied and reduce grease usage costs too. (Figure 1)

Computer based systems – Systems connected to a PC grant full control over manual lubrication by reducing over-lubrication and missed lubrications. Connected Digital grease meters with transponders display planned lubrication amounts for each point plus measure and record grease dispensed at each point, thereby preventing lubrication points from being overlooked. (Figure 2)

Continuous monitoring systems – Where continuous monitoring of lubrication in lubricating systems is required, automated monitoring systems that connect to control units or mill systems with pulse inputs are optimal. (Figure 3)

“The Totally Emptied Concept” – Loss-free emptying of pails, kegs or drums

Conventional grease pumps leave 10-20% of the grease behind. Utilizing Pneumatic 1:65 grease pumps with an air driven pump mechanism can result in cost savings and environmental benefits too by ensuring that the maximum volume of grease is dispensed out of every single pail, keg and drum. Pumping innovation that challenges conventional construction is achieved with a floating follower plate design, creating a completely closed grease handling system to empty each container fully. (Figure 4)

GREASE MANAGEMENT – BEST PRACTICES OVERVIEW

1) Utilize digital grease meters that mount to existing greasing equipment to dispense the correct amount of grease into each bearing.

Figure 1

Figure 1

2) Connect grease meters with transponders to a PC program to manage planned lubrication amounts for each point and prevent missed points.

Figure 2

Figure 2

3) For continuous monitoring, automated monitoring systems connected to mill systems with pulse inputs are optimal.

Figure 3

Figure 3

4) Don’t leave any grease behind! Innovative Pneumatic 1:65 grease pumps empty each grease container fully.

Figure 4

Figure 4

PUTTING IT ALL TOGETHER

Implementing proactive best practices for both circulating oil (read the full article on oil lubrication here) and grease lubrication can increase overall production efficiency and reduce the number and seriousness of unscheduled shutdowns.

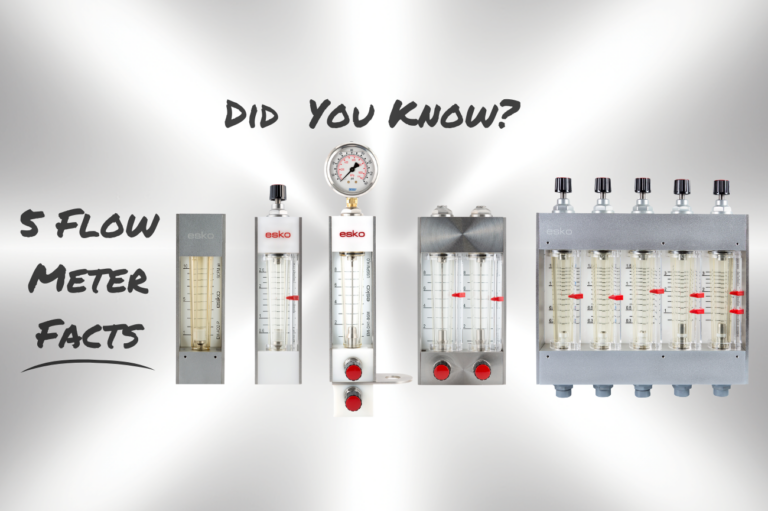

The flow monitoring experts at ESKO are available to share knowledge and decades of industry experience to assist with putting lubrication practices into action.

ESKO is a North American based stocking distributor of European-made expert equipment for central lubrication and grease handling.

At ESKO Pacific, we’ve been working with paper mills for over 40 years supplying variable area flow meters constructed from high quality components. Contact us today to see how we can help keep your mill running smoothly with tried-and-true technology.

ESKO Pacific variable area flow meters are constructed using a variety of materials for low to industrial level flows. View our product line.