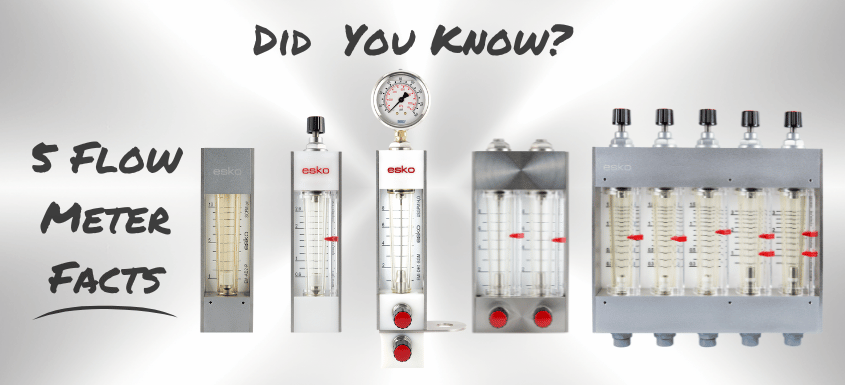

Good to Know Flow Meter Facts

Are any of these new to you? Some flow meter features can catch users by surprise.

FACT 1: Variable area flow meters with free floats won’t work sideways – WHY?

Because they rely on GRAVITY.

Simply put, the flow of liquid or gas through a flow meter pushes the internal float upward while gravity pulls the float downward. The resulting equilibrium position of a free-floating float in a tapered tube provides an indication of the flow rate. Flow meters come standard or custom calibrated for the specific combination of media, floats, and tube taper. If this type of flow meter is not mounted vertically, the float position will not indicate the actual flow. Read more about floats.

FACT 2: Transparent plastic is basically plastic – RIGHT?

Never ASSUME all plastics behave the same.

There are many different transparent high-performance polyamide (nylon) plastic polymer materials that look similar. It’s not always possible to tell by appearance whether a flow tube is made of polycarbonate, Trogamid®, PSU, Grilamid®, acrylic or one of a myriad of other clear polymers created for a particular purpose such as thermal and chemical resistance etc.

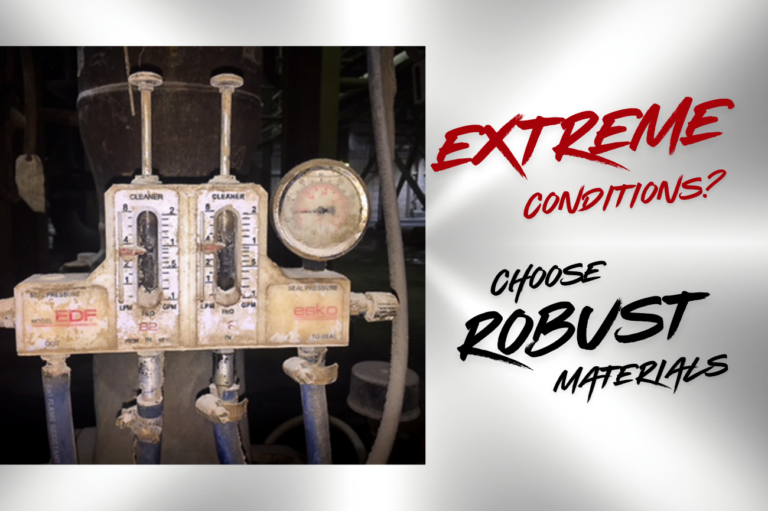

For successful flow measurement, it’s wise to consider what will happen to the flow tube material when it meets various acids, bases, chlorinated solvents or combinations of chemicals or contaminants that may normally or occasionally appear in the flow media. Furthermore, the integrity of flow tubes may be affected by constant or intermittent elevated thermal and/or mechanical stress. Choosing the right flow tube, float, connection/fitting material and even the right O-ring material can make or break the longevity and reliability of a flow meter.

Flow tube materials have many different attributes.

FACT 3: Flow meters are designed for EITHER liquids or gases – NOT BOTH.

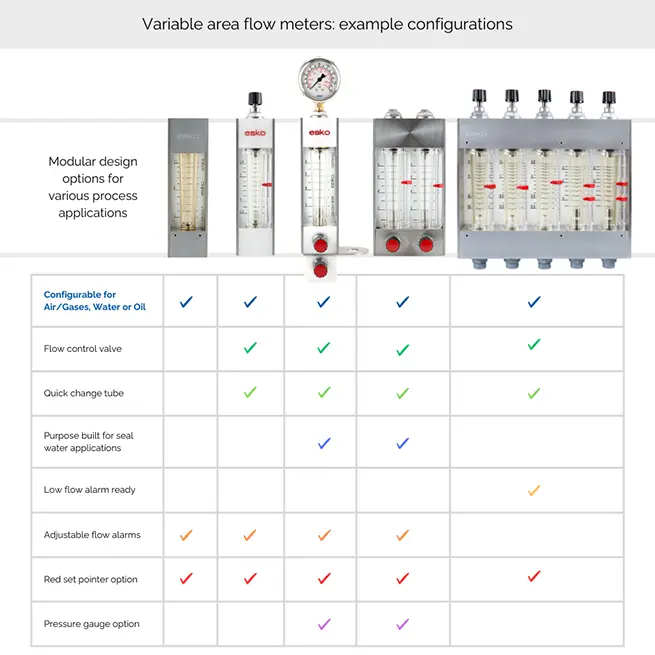

NOT NECESSARILY. ESKO can configure a basic tapered tube flow meter (for example the ESKO medium range Model EM variable area flow meter) to measure various media including air, gases, water, oil or other process flows.

It is in fact possible to have two different scales on a single flow meter and they don’t even have to be for the same flow media! Dual-scale indication in both LPM and GPM is standard on the popular ESKO ESF seal water meter.

FACT 4: Installation can get tricky and costly when fittings don’t match.

DOESN’T HAVE TO. Well-designed flow meters can be built to fit with connections that make installation a breeze.

Whether it’s NPT threads, straight tubes, hose barbs, compression fittings or a combination of fittings (and fitting materials) for different size or type inputs and outputs. Modular designs are key to simplifying in-line installations in difficult-to-reach locations. (Pro tip: Explore whether lower cost PVC or Delrin connections may be adequate.)

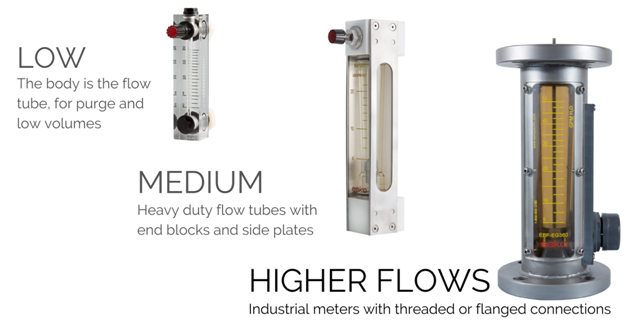

Various connection options are available for easy installation.

FACT 5: Is it important to keep flow tubes clean?

YES, BUT GENTLY and SAFELY! Cleaning with alcohol may cause problems.

To keep flow indication visible, keep your flow tubes clean. Just be careful though because plastics and alcohol don’t mix well! Solvents such as acetone and alcohol may damage polymer flow tube materials and make them more likely to crack or unexpectedly shatter. The best way to clean flow tubes is dish soap and a scrubby brush. (Final Pro survival tip – stay safe, whatever and wherever you’re cleaning, NEVER mix bleach and alcohol. This combination creates chloroform, a toxic compound that emits toxic and corrosive fumes that can cause serious health effects if inhaled.)

Don’t let this happen! Clean your flow meters gently.

At ESKO Pacific, we’ve been working with paper mills for over 40 years supplying variable area flow meters constructed from high quality components. Contact us today to see how we can help keep your mill running smoothly with tried-and-true technology

We encourage you to ‘ASK US HOW’