Flow meters vs. Winter

How to prevent and manage flow meter issues due to freezing

Extreme or prolonged cold weather can make maintaining process flows and accurate flow measurement challenging. Temperature drops not only affect viscosity of flow media but related metering components too: piping, fittings, and every component of a flow meter needs to be able to withstand freezing.

Tips to keep processes running when the temperature dips:

- Prevent component failure by clearing any flow blockages and identifying and repairing leaks promptly.

- Instrument enclosures and heaters can be helpful but additional costs and maintenance demands may not be warranted when warmer weather returns.

- The key preventative step is having the right flow meter with the appropriate component material selections in the first place. (Read about choosing the right flow meter here).

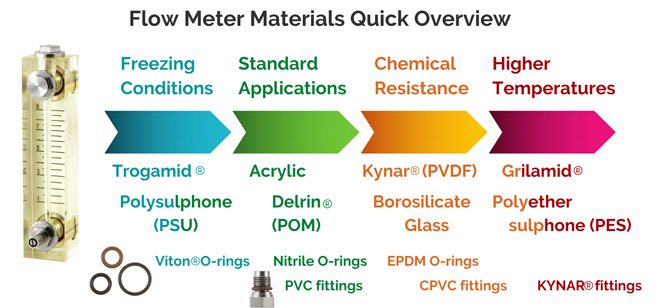

Each flow meter component should be considered: tube material, end block material, connections/fittings, floats, valves, and o-rings all need to hold up through a freeze. Acrylic is known for its overall durability and functionality, but it’s not the optimal choice for all conditions. When the contents of an acrylic flow tube freeze, the acrylic may crack and cause leaks. The size and taper of the tube are also a factor. Polymers generally offer better resistance to freezing, extreme heat, and chemicals because they are less likely to break if they crack.

The graphic below gives an overview of material choices for varying conditions. Bottom line: Trogamid® flow tubes offer the best prevention against unwanted breaks due to freezing.

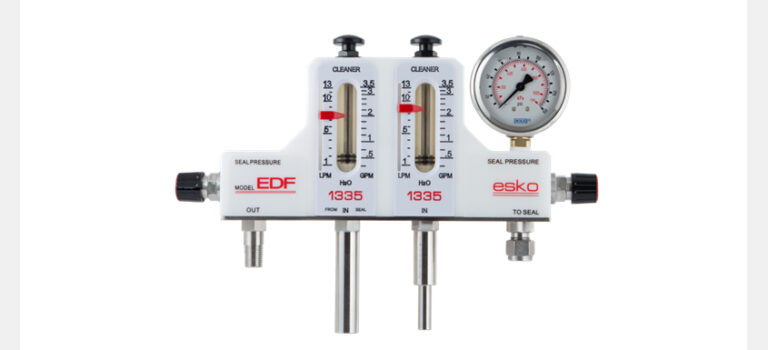

ESKO Pacific variable area flow meters are constructed using a variety of materials for low to industrial level flows. View our product line.

At ESKO Pacific, we’ve been working with paper mills for almost 40 years supplying variable area flow meters constructed from high quality components. Contact us today to see how we can help keep your mill running smoothly with tried-and-true technology.