Flow Measurement Accessories & Add-ons

Fine tuning your flow monitoring?

What if process conditions change?

How to fine tune your flow monitoring installations with optional accessories and add-ons for additional operational and cost benefits.

After installation, the benefits of modular flow meter design become apparent. If the process or operational needs change, it’s possible to consider enhancements and tweaks to existing flow meters. While some accessories and add-ons work across various types of flow meters, some are flow meter type specific. Let’s review the most popular ones (watch the video here):

- Accessories for Seal Water Meters

Proximity Alarm – To protect and cool seals, operators need to know immediately when water flow into a seal drops or stops. Alarm sensors detect the proximity of the elongated metal float to provide effective low flow indication without false alarms for temporary upward water pressure fluctuations. If alarm sensors aren’t supplied with the original flow monitor, they can be easily added afterwards to the back of the unit.

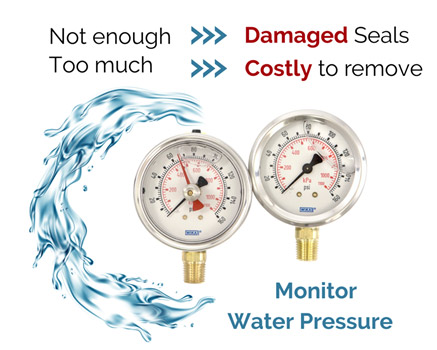

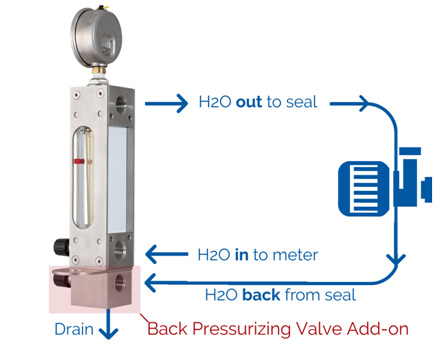

Pressure Gauges – Flow meters provide information about flow into the seal but adding a pressure gauge indicates seal water pressure, which is critical for longevity of mechanical seals. Gauges are available with or without a red set pointer which can be used to indicate whether there is sufficient seal pressure. Real-time visual monitoring can prevent excess water finding its way into the process, which can be costly to remove.

Back Pressurizing Valve – Seal manufacturers provide specifications for optimal operating conditions. Simply put, the goal is to ensure both proper flow and proper pressure. A back pressurizing valve controls the water going into the drain. Installing a back pressurizing valve provides control of seal water pressure and prevents undesired backflow.

Check valve – Regular fittings provide a clear opening all the way through the monitoring unit which means that backflow can push process fluid back towards the flow meter. Process fluid in the hoses, valves or flow meters can cause plugging. Adding a check valve with an internal ball valve prevents backflow.

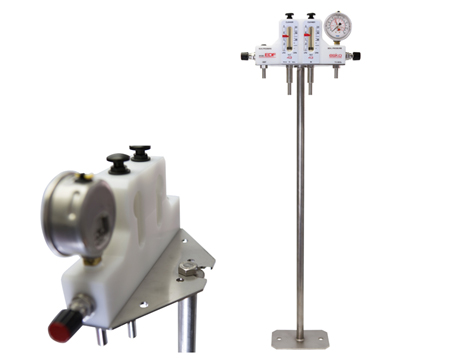

Stands – Seal water meters supplied with mounting brackets are commonly mounted on bolts in the process area near seals. If easy mounting is not available in close proximity, these meters can also be mounted on a durable SS stand. Facilitating easy visual access can assist operators in managing water consumption and seal health.

- Accessories and Modifications for Tapered Tube Variable Area Flow Meters

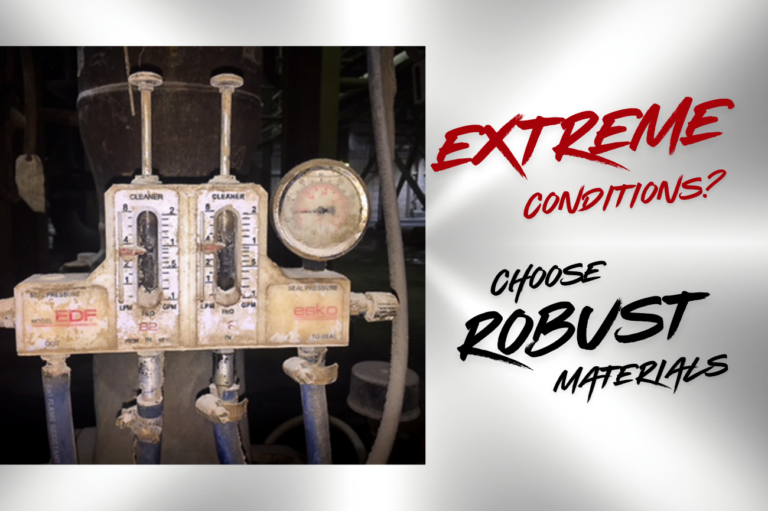

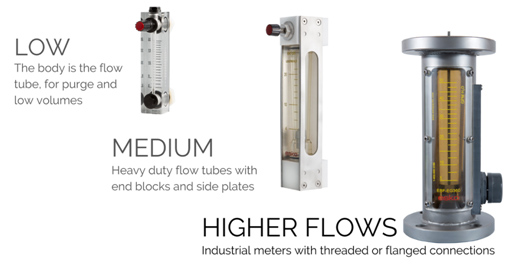

Variable area flow monitors are a popular solution for flow measurement ranging from purge flows to large industrial flows. Flow meters are usually configured for specific flows and media, however accessory and modification options may still be possible for some meters after they are put in service.

Variable Area Meter Choices

Popular add-ons and modifications for many variable area flow meters include:

Low Flow/High Flow Alarms – In standard variable area flow meters, a metal float moves up and down the flow tube to indicate flow through the meter/process. Proximity sensor alarms simply detect the presence or absence of the float at a specific point. Well designed flow meters have multiple alarm capability for an alarm at the bottom for low flow/no flow indication and multiple side alarms to indicate if flow varies from the desired range.

Proximity alarms can be added with the initial installation or added later if operators want more information or more precise monitoring tools due to process refinements. It’s helpful to stay aware of too much oil in the lubrication system as overflow can cause hazardous oil slicks on the floor of the paper machine. It’s also critical to know if flow is too low as bearings may be compromised if lubrication is interrupted. Read more about circulating lubrication oil monitoring applications and systems here.

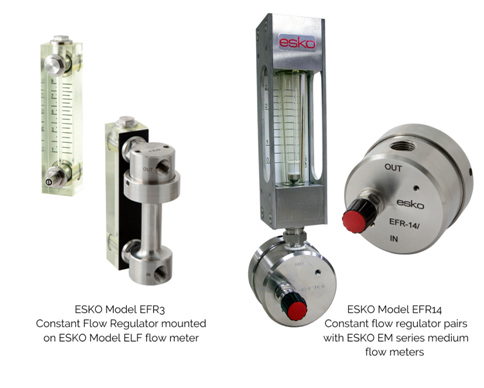

Constant Flow Regulators – ESKO Model ELF low flow and Model EM medium flow variable area meters have a modular design that allows for the installation of a constant flow regulator add-on at the back or bottom of the meter. Adding a constant flow regular to in-line flow meters can reliably stabilize flow in applications where supply or back pressure varies. These regulators are designed to provide a constant flow of liquids or gases, regardless of pressure variations. Read more about constant flow regulator function and applications here.

Pointers – ESKO Model EM flow tubes are designed to accommodate a simple add-on clip with a red flow marker, or several markers. These are a handy reference to confirm visually if the flow indicator is in the correct range. One marker can indicate desired flow or a set of two high/low markers can be added for optimal range cues.

Valves – ESKO Model EM Flow meter’s modular design allows for adding a back pressurizing valve. Model EM meters are used in seal water applications that require larger flows than the commonly used Model ESF designed specifically for seal water monitoring. The Model EMI configuration with a back pressurizing valve allows for finer control of the flow rate. Some meters can handle two valves.

Scales/Recalibration – If flow media or process changes occur, reconfiguration of flow meters with replacement of a flow scale is possible (assuming the flow range for the meter type allows it). If the oil in a circulating oil system is changed, replacement scales (and metering components as required) can be installed to accommodate a new oil viscosity. Custom calibration or recalibration may also be helpful when changing measurement units (ie. gallons, litres, pints). For example, dual indication of gallons and litres of flow on the same scale or other such customizations are possible.

Rebuilds – Flow tube materials are originally matched to flow media but if liquids or additives change after installation it is possible to replace the flow tube material to accommodate new media. Range changes are also possible on some flow meters by changing the tube size and material or replacing floats with a different size/shape/weight. On ESKO Model ELF flow meters, scale modification is also easy by unscrewing the top and bottom valves, removing the scale, and replacing it with a new one.

Pressure gauges – can be added onto some ESKO Model EM flow meters. On the Model EMI, the plug on top of the dummy valve can be unscrewed and replaced with a pressure gauge.

Spare Parts – Normal wear and tear and breakage happens. Keeping spare parts and maintenance kits on hand, including replacement tubes, O-ring kits, hand knobs, and red set pointers can help ensure continuous smooth operation. Choosing meters with modular designs allows for easy repair, maintenance, and add-ons to keep up with process changes and improvements. Modular design also allows for easy tube replacement, watch the short video here.

For more details and information on installation, servicing and reassembling variable area flow meters, get in touch with one of the experts at ESKO Pacific. We are pleased to share further detailed tips on troubleshooting, tools, and best practices for flow metering as well as offer factory refurbishing or replacement of every meter we’ve supplied since 1982.

ESKO flow meters are built in North America, so we have the full range of replacement parts in stock, ready to go.