ESKO Pacific adapts to the changes

Originally published on Paper Advance

“There is nothing permanent except change” wrote Heraclitus, an ancient Greek philosopher. This observation holds particularly true today as industries across the globe undertake the task of adapting to new demands, fluctuations in resources, volatility in supply chains, and the overwhelming uncertainty around ultimate impacts on the global economy.

. How is ESKO Pacific’s past helping you adapt to current circumstances? And what changes do you see happening in industry generally?

ESKO is based on the concept of sharing proven instrumentation solutions. ESKO’s founder, Esko Venalainen was an instrumentation specialist who personally worked on various development projects when infrastructure spending in North America was booming. He was part of the global technology bridge, helping bring European technology and practices to North America by personally visiting pulp and paper mills all over the continent. He collected and shared industry best practices, simultaneously establishing a network of agents and partnerships to serve process industries.

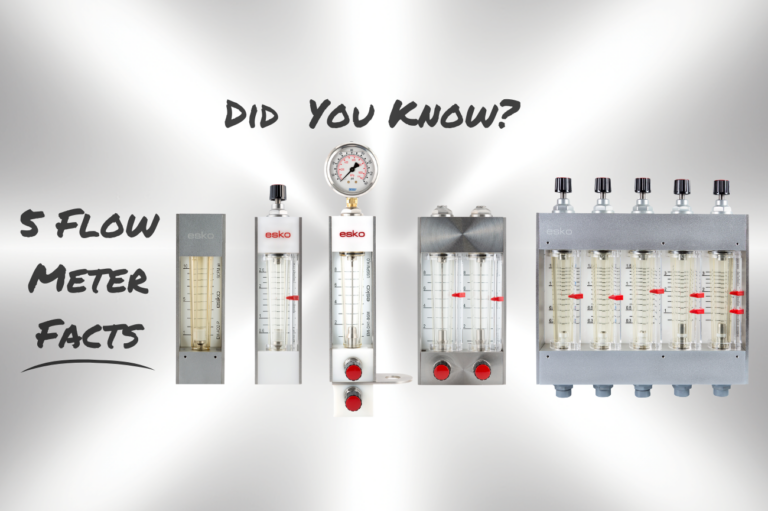

After acquiring this solid insight into industry needs, ESKO launched its own line of flow metering products and started manufacturing in the Pacific Northwest in 2006. Esko’s family and loyal employees continue to share best products and practices for process optimization, offering both manufacturing and technical services that are responsive to evolving customer needs.

During this year, pulp and paper manufacturing has been recognized by governmental authorities as a priority manufacturing activity; a critical component in global supply chains. As individuals and companies make the shift to adaptive work situations, we see pulp and paper manufacturers working hard to respond to the surge in demand for paper, tissue and cardboard to support uninterrupted food supply and medical support activities, among other global response measures.

Manufacturers are responding to today’s challenging circumstances by simplifying focus to just keeping operations running consistently with minimal process interruptions. We see customers putting their best efforts into managing all available resources. They are maintaining and verifying consistent supply of equipment and inputs to continue quality production in a high demand environment.

The current crisis has similarly refined and simplified ESKO’s focus. A big part of our job in this year is to quickly get our North American made flow meters delivered to help our customers maintain operations.

. What makes ESKO products so advantageous to operators?

“Doing the common thing uncommonly well.”

The bulk of ESKO manufactured flow metering products are based on established, time-tested technology.

Variable area flow metering technology dates back to the early 1900’s when ‘rotameters’ were developed utilizing a rotating float to add stability. Today, not all variable area flow meters have a rotating float, but the terms ‘rotameter’ and ‘variable area flow meter’ are still used interchangeably.

Variable area flow meters are the mainstay of the ESKO product line. Many of our customers are simply looking for proven and low-cost solutions. This is particularly true today when capital projects are being scrutinized or deferred and the primary operational goal is to keep processes running.

Variable area flow meter with tapered tube and float with guide rod.

“Back to basics – how does a Variable Area flow meter work?

The basic principle of a typical variable area flow meter is simple: an upright tapered tube contains a free-floating float. Fluid flowing through the tube, from bottom to top, forces the float upward, countered by gravity. The point at which the float stabilizes indicates the volumetric flow rate, as displayed on a scale on or near the metering tube.

In addition to providing basic flow volume indications, variable area flow meters are ideally suited for applications where a flow vs. no-flow determination is key. Beyond that, incorporating modifications and improvements including for example guide rods, proximity sensors, control valves, constant flow regulators, etc., opens up a myriad of solutions for various process applications. ESKO innovations and process solutions derive from years of experience in customizing float shapes, float and tube materials, fittings, and other modifications based on application requirements such as temperature, flow media and flow volume.

In addition to providing reliable variable area flow meters, the ESKO team offers ways to automate and merge variable area products with newer technology by providing various levels of continuous lubrication monitoring systems. Solutions range from single flow meters, to flow meter banks, to comprehensive automated monitoring systems with DCS outputs and trending.

Variable area flow meter with free-floating float.

. What are your objectives in developing the North American market?

The ability to adapt is critical, both for ESKO and for our customers. We aim to understand process optimization from the customer’s perspective because it enables us to meet unique and complex customer needs in the most cost-effective way.

What truly makes ESKO stand out over the last four decades, however, is our ongoing commitment to providing reliable, modular built, easy-to-maintain products. This is especially true today as many of the conversations we’re having with customers are short:

“We need a replacement for the flow meter you provided ten years ago.”

“We need spare parts and new O-rings for the flow meters you sent us last year.”

“We need it now!”

ESKO’s guiding vision is to supply products that minimize waste, reduce energy consumption and maximize process uptime. We want to be part of process optimization across the continent and beyond.

Long term relationships with customers are allowing ESKO to facilitate the sharing of valuable know-how between our team and our customers and stay on track with our longer-term goals despite the current challenges industry is facing.

Our primary customer base continues to be the pulp and paper industry, but in looking further to develop the North American market ESKO is actively adapting our expertise to connect with other process industries with similar flow metering and monitoring needs: mining, manufacturing, petrochemical, food processing and waste water management. This is important as sustainability initiatives and mandates on water and energy use gain momentum.

. Can you tell us more about your capabilities?

“ASK US HOW” is our motto. In-house experts strive to provide creative solutions for process flow and related paper processing matters. In addition to manufacturing flow meters, ESKO offers world class in-house developed felt guiding systems and represents select complementary European product lines because we believe in the quality of those products and carry inventory to make them accessible to the North American market. Popular lines include: Assalub grease lubrication products, DropsA lubrication systems and Tempress level and pressure gauges.

Our President, the founder’s son, has a background in computers and technology, guiding technical processes and technological product advancements coupled with decades of continuity with the company. A Professional Engineer heads up our sales department to make sure it has the expertise to answer customer queries effectively and to engage in meaningful technical discussions. We have additional in-house and partner experience with industrial equipment manufacturing, electronics components, mechanical engineering, quality control in manufacturing, and experienced machinists with decades of combined experience working with manufacturing materials.

. What are your objectives for ESKO in the next year? Longer-term?

In the near term, we are prioritizing employee health to ensure business continuity. We continue to maintain our standard manufacturing and delivery schedules and remain dedicated to keeping our manufacturing lines and customer service team operating smoothly. Our team is fulfilling customer orders in a timely manner during ever-changing circumstances. Fulfilment lead times are optimized by maintaining component inventory. We are able to respond quickly to needs for high demand products and will continue to monitor the global situation and industry developments to make operational changes as circumstances require.

ESKO has been in business for nearly 40 years and we look proudly and confidently toward the future. Our long-term objectives are to stay connected with our customer base, connect with new industries and emerging young professionals, all while staying ahead of the curve with what’s happening in industrial practices across the globe.

Despite recent challenges, we are steadily improving our business and manufacturing facilities to keep our delivery times exceptional. ESKO is growing at a healthy pace, focussing on continuity and quality by balancing the needs of established customers with the exploration of new markets in North America and abroad.

. What is your response to growing interest in sustainability initiatives and practices?

ESKO anticipates and is responding to increased interest in environmental controls and adaptations. There is growing interest in raw material component inputs, for example replacing single use plastics with renewable fibre options. Flow monitoring instruments are also fundamental in water use management and conservation.

At the mill level, we’ve seen a continued shift towards cost-saving maintenance programs rather than full replacement. Our customers are stocking spare parts and replacement flow meters as part of efforts to reduce unscheduled downtime and conduct efficient maintenance programs. With modular design principles, ESKO is ready to make component advancements and to support initiatives which enable refurbishment rather than replacement of installed products. We are reminding customers that we provide factory refurbishing services and spare part kits.

ESKO is looking for ways to support developing sustainability standards and industry initiatives, particularly relating to process monitoring.

. How do you see commerce trends affecting the pulp and paper industry?

Looking forward, as a result of the digital revolution and trend towards digital commerce, we foresee a further shift away from print paper towards packaging materials manufacturing, particularly lightweight packaging. Recyclable paper products are also surging in popularity. Industry is responding to these trends by adapting technology and processes and we believe ESKO will be a partner in those shifts at the process level.

The use of process data as part of optimizing production is increasingly common. Artificial intelligence systems and the internet of things are developing quickly. ESKO is excited to be part of the data revolution. We’re refining methods of recording and trending process data and interfacing to existing mill systems.

. What do you think is the most important quality for success?

Success is founded on vision and commitment. ESKO is passionate about our history, accumulated experience and the resulting products we make today. We place a high value on customer and partner relationships. We prioritize integrity in all aspects of our business dealings and in the way we treat our team. We pride ourselves on being a reliable source of straightforward information about metering, monitoring and process optimization, whether it results in an immediate sale or not.

We strongly believe that transparent communication, stepped up corporate social responsibility and collaboration on solutions will help guide us globally through this challenging period.