Versatility of Variable Area Flow meters

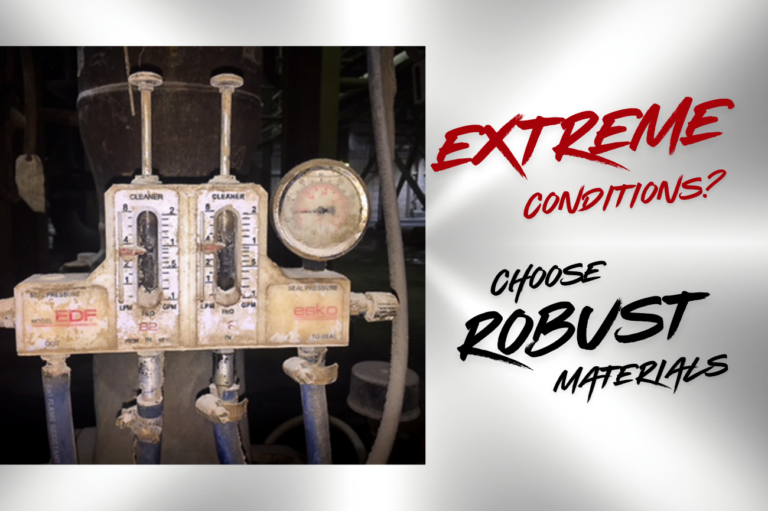

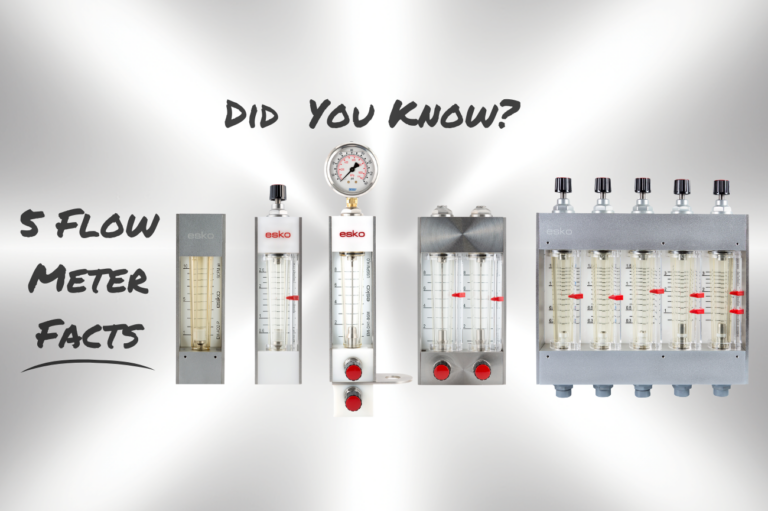

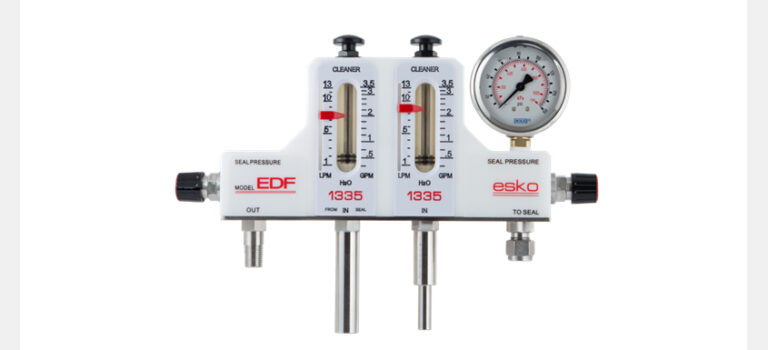

Variable area flow meters are used in pulp and paper manufacturing and other process industries, such as chemicals, oil and gas, mining, food and beverage production, and more. Its popularity stems from its uncomplicated design, cost efficiency, and adaptability to challenging environments.