EM MEDIUM RANGE METERS

VERSATILE INDUSTRIAL FLOW METER

APPLICATIONS

- Sealing and cooling water measurement

- Lubrication oil measurement

- Mixing of gases

FEATURES

- Solid construction for reliable operation

- With or without flow control valve

- Large selection of flow ranges

- Easy to install, clean and maintain

- Can be fitted with flow level alarm

- Impact resistant flow tube

OPTIONS

- Inductive adjustable alarm

- Polysulphone (PSU) flow tube

- Viton® or EPDM Seals

- Pressure gauge (optional red set pointer)

- Constant flow regulator (Model EFR)

- Flow Marker (Model EMP)

- Calibration for non-standard liquids & gases

INDUSTRIAL FLOW METER

For medium flows of liquids or gases

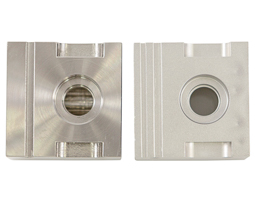

SOLID CONSTRUCTION

For demanding industrial applications

VERSATILITY IS KEY

All EM type industrial flow meters feature robust solid stainless steel side plates with various end block materials, float materials, and metering tube options to suit most applications and budgets. Versatility is the cornerstone of EM meters; the base model EM can be readily adapted to various configurations and uses. A key design feature is an optional built-in flow control valve.

TECHNICAL SPECIFICATIONS

| MODEL | EM-A | EM-D | EM-S |

|---|---|---|---|

| BODY MATERIAL (END BLOCKS) | ALUMINUM | DELRIN® (POM) | SS316 |

| Metering tube | Grilamid® TR 55 or Polysulphone PSU | Grilamid® TR 55 or Polysulphone PSU | Grilamid® TR 55 or Polysulphone PSU |

| Float material(s) | SS316 / Delrin | SS316 / Delrin | SS316 / Delrin |

| O-ring seals | Nitrile (Viton® or EPDM optional) | Nitrile (Viton® or EPDM optional) | Nitrile (Viton® or EPDM optional) |

| Maximum pressure | 440 psi | 290 psi | 440 psi |

| Maximum temperature Grilamid® tube | 176°F / 80°C Grilamid® tube | 176°F / 80°C Grilamid® tube | 176°F / 80°C Grilamid® tube |

| Maximum temperature Polysulphone (PSU) tube | 248°F / 120°C PSU tube | 248°F / 120°C PSU tube | 248°F / 120°C PSU tube |

| Connections | 1/2″ NPT | 1/2″ NPT | 1/2″ NPT |

| Weight | 1.7 lb (0.75 kg) | 2.1 lb (0.95 kg) | 4.4 lb (2.0 kg) |

BUILD OPTIONS: Removable flow marker included, calibration for non-standard liquids & gases

OPTIONAL ACCESSORIES: Inductive adjustable alarm, pressure gauge (with optional red set pointer), pair with constant flow regulator model EFR14