EMO MEDIUM RANGE METER

INDUSTRIAL FLOW METER, WITH VALVE ON OUTLET

APPLICATIONS

- Typically used in lubrication oil measurement

- Suitable for all liquids

FEATURES

- Solid construction for reliable operation

- With flow control valve on outlet

- Large selection of flow ranges

- Easy to install, clean and maintain

- Can be fitted with flow level alarm

- Impact resistant flow tube

OPTIONS

- Inductive adjustable alarm

- Polysulphone (PSU) flow tube

- Nitrile seals standard

- Viton® or EPDM Seals optional

- Pressure gauge (optional red set pointer)

- Flow Marker (Model EMP)

- Calibration for non-standard liquids

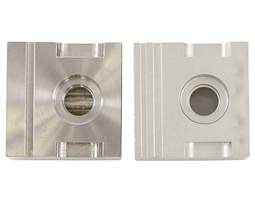

INDUSTRIAL FLOW METER

For medium flows of liquids

SOLID CONSTRUCTION

For demanding industrial applications

CUSTOMIZABLE FLOW MONITORING

Ideal for medium size flows up to 2.5 GPM / 10 LPM in industrial applications. Model EMO meters are designed with a built-in flow control valve on the outlet. In oil lubrication applications, the flow control valve on the outlet allows for full-pressure oil flow through the flow tube feeding oil to a bearing. This design is optimal for accurate measurement of bearing lubrication.

The base Model EM is available with no flow control valve and the Model EMI features a flow control valve on the inlet. Like the base model single tube Model EM flow meter, Model EMO meters feature robust stainless steel side plates, several choices of end block materials, float materials, and heat resistant Grilamid or impact-resistant PSU tubes. The Model EMO is also available in a multi-tube model configured for lubricating oil monitoring systems. A large selection of flow ranges with custom calibration for different operating conditions is available.

SIMPLE TO INSTALL AND MAINTAIN

The Model EMO flow meter is designed for easy installation, cleaning, and minimal maintenance. O-ring replacement is recommended after several years in service, depending on operating factors and conditions such as temperature and flow media. ESKO also offers budget-friendly factory refurbishing and spare parts to optimize maintenance programs and help minimize unexpected downtime.

ALARM OPTION

EMO meters can be fitted with inductive low flow alarms. A slotted side plate allows for an adjustable flow level alarm.

TECHNICAL SPECIFICATIONS

| MODEL | EMO- | EMO- |

|---|---|---|

| METERING TUBE | GRILAMID® TR55 | POLYSULPHONE (PSU) |

| Body material | Aluminum | Aluminum |

| Metallic parts | SS316 | SS316 |

| O-ring seals | Nitrile (optional Viton® or EPDM) | Nitrile (optional Viton® or EPDM) |

| Maximum pressure | 440 psi | 440 psi |

| Maximum temperature | 176°F / 80°C | 248°F / 120°C |

| Connections Inlet | 1/2″ NPT | 1/2″ NPT |

| Connections Outlet | 1/2″ NPT | 1/2″ NPT |

| Weight | 1.7 lbs / 0.75 kg (per tube) | 1.7 lbs / 0.75 kg (per tube) |

BUILD OPTIONS: Flow tube material, custom calibration for all operating conditions, O-ring seals

OPTIONAL ACCESSORIES: Can be fitted with inductive low flow alarm, pressure gauge (with optional red set pointer), flow marker (Model EMP)