EGL OVAL GEAR METERS

MULTI-FLOW MONITORING

APPLICATIONS

- Lubrication oil monitoring

- Industrial fluid flow monitoring

- Process control

FEATURES

- High visibility of oil flow indication through robust transparent cover

- 1-12 meters on manifold

- Insensitive to viscosity variation

- Large viscosity range (30-1000 cSt)

- Pulse output

- Solid construction

OPTIONS

- Nitrile or Viton® seals

- Multiple connection options

HOW OVAL GEAR METERS WORK

EGL oval gear meters are based on positive displacement technology which measures flow by counting the rotation of meshed oval gears. Flow through the housing causes a gear pair to rotate and each rotation represents a precise volume of fluid. Through each half rotation, a fixed amount of flow media is moved from the inlet to the outlet of the oval gear meter. Measurement is facilitated by an inductive proximity sensor which generates a pulse output for each half rotation of one gear.

OPERATING PRINCIPLE

EGL oval gear meters are based on positive displacement technology which measures flow by counting the rotation of meshed oval gears. Flow through the housing causes a gear pair to rotate and each rotation represents a precise volume of fluid. Through each half rotation, a fixed amount of flow media is moved from the inlet to the outlet of the oval gear meter. Measurement is facilitated by an inductive proximity sensor which generates a pulse output for each half rotation of one gear.

CONSISTENT MEASUREMENTS

Oval gear flow meters are ideal in lubrication systems because they are not sensitive to viscosity variations over a wide range. As oil temperature increases, viscosity decreases. Using a conventional variable area flow meter can result in a change of flow indication as circulating oil warms up to operating temperature. Oval gear meters will provide consistent and accurate flow measurement in varying operating conditions.

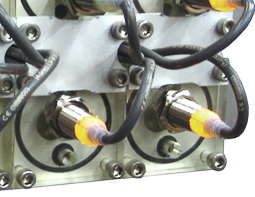

EASY MONITORING OF MULTIPLE LUBRICATION POINTS

Model EGL meters can be customized in units with up to 12 flow points with a single manifold inlet to simplify installation. Flow is visible through the clear cover, and a blinking LED indicator on the flow sensor is visible from a distance. EGLs installed in banked configurations allow for quick verification of multiple flows with a single glance. Lubrication panels with multiple banks of EGLs provide a wider view of lubrication system status.

ROBUST AND CUSTOMIZABLE

EGLs are constructed with Trogamid, aluminum and stainless steel components to withstand challenging operating environments. Multiple O-ring seal options facilitate installation in various types of industrial fluid flow monitoring and process control applications.

TECHNICAL SPECIFICATIONS

| MODEL | EGL |

|---|---|

| FLOW RATE | 1, 3 OR 6 LITERS / MINUTE (2, 6 OR 12 PINTS / MINUTE) |

| Base & metering blocks | Aluminum |

| Oval gears | Grilamid® |

| Gear covers | Trogamid® |

| Valve spindles | SS316 |

| O-ring seals | Nitrile (optional Viton® or EPDM) |

| Oil filtering | 10-15 micron recommended |

| Maximum pressure | 10 bar @ 80°C / 145 psi @ 176°F |

| Maximum temperature | 80°C / 176°F |

| Connections | Inlet 1″ NPTF Outlets 1/2″ NPT female threads |

| Build options | O-ring seals, connections, number of meters on manifold |