ESTRAC 2000 Non-contact felt guide system

FEATURES

- Improves run time – reduces unscheduled shutdowns

- Increases fabric life

- Eliminates wear and tear of edge

- Minimizes cross machine movement of fabric

- 4-20mA loop output can be adapted directly to any roll guiding system

- Output can be monitored in machine control room to provide continuous information on cross machine position of the fabric

BENEFITS

- No moving or wearing parts

- Fiber-optic measurement ensures that all electrical components are outside the process area

- Non-contact measurement using pulsed infrared light

- All stainless construction

- Continuous air purge and water spray keep the optics clean for proper operation

- Simple and easy to install and use

- Does not require daily cleaning or maintenance

- Designed for harsh environments with optimal components, resulting in extremely low system maintenance

SUPERIOR EDGE TRACKING

AND CONTROL

NON-CONTACT FELT GUIDING

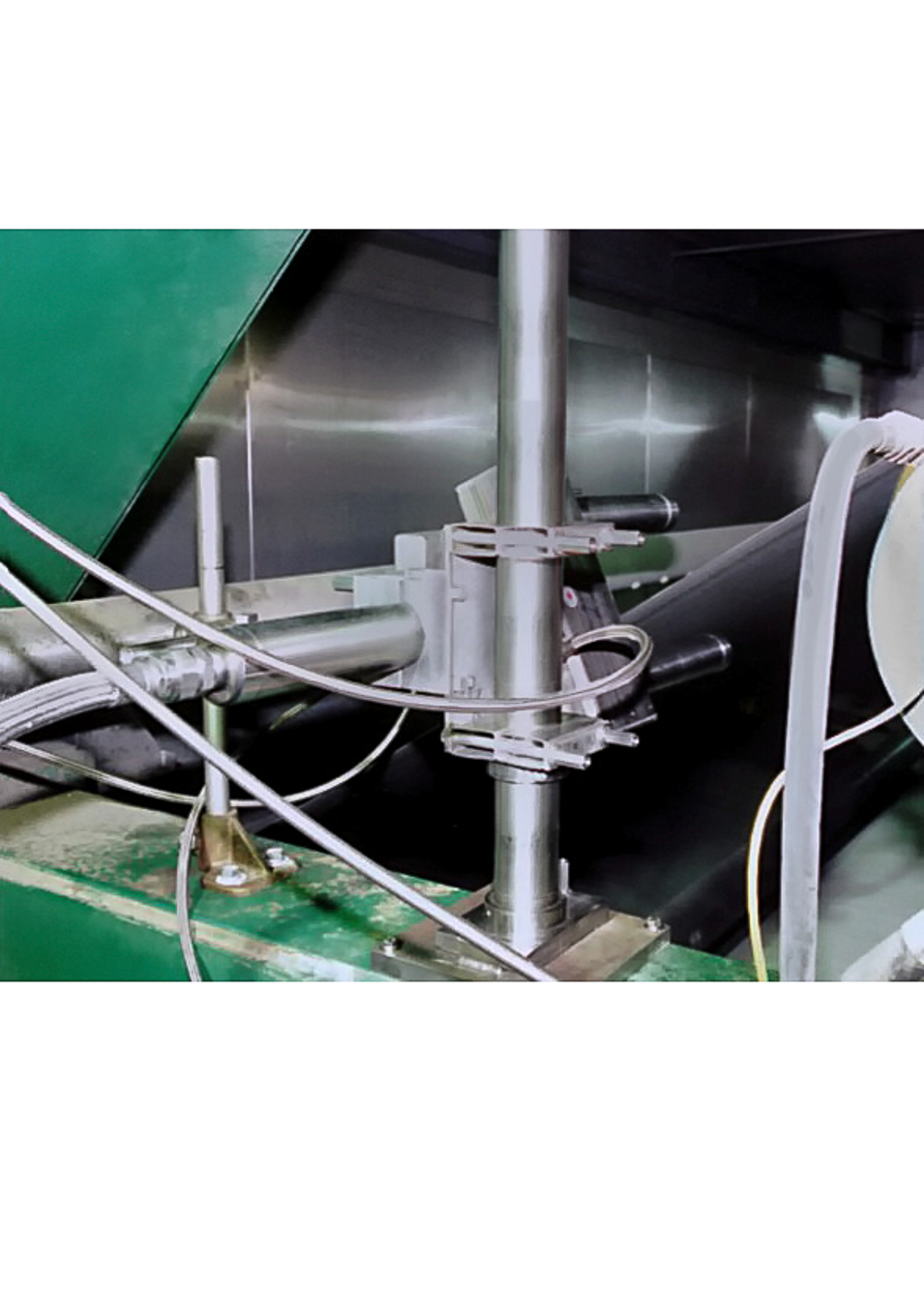

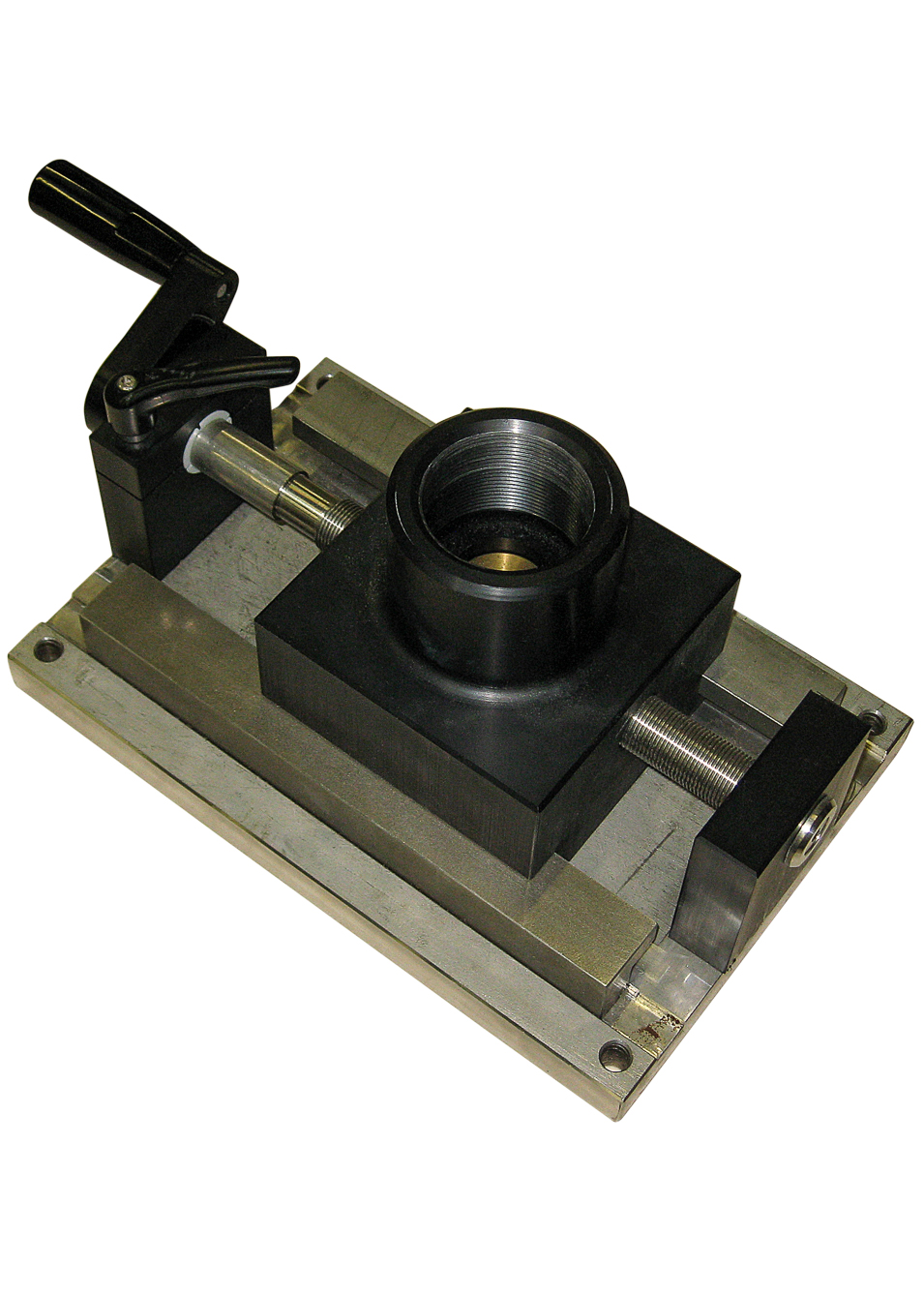

The ESTRAC 2000 edge tracking system is one of the most advanced non-contacting measurement and guiding system for felts and fabrics. The unit can be placed into any part of the machine, even where extreme heat and humidity demand special requirements for equipment.

Originally developed for pulp and paper applications, these systems can also be used on machines for the the production of photographic film, Kevlar, fibre-glass roofing material, or any device requiring edge tracking and control.

TECHNICAL SPECIFICATIONS

| MODEL | ESTRAC 2000 |

|---|---|

| MEASUREMENT | Modulated infrared light (5 kHz) |

| Measurement range | 50mm, 100mm or 150mm |

| Measurement accuracy | < 1 mm |

| Output signal(s) | 4-20mA current loop 8-52 psi pneumatic signal |

| Operating voltage | 24 VDC, 100-240 VAC |

| Fiber-optic cable length | 10, 23 or 31 feet |

| Material | Stainless Steel |

| Maximum operating temperature | Measuring fork: 320 F (160C) Control cabinet: 122 F (50C) |