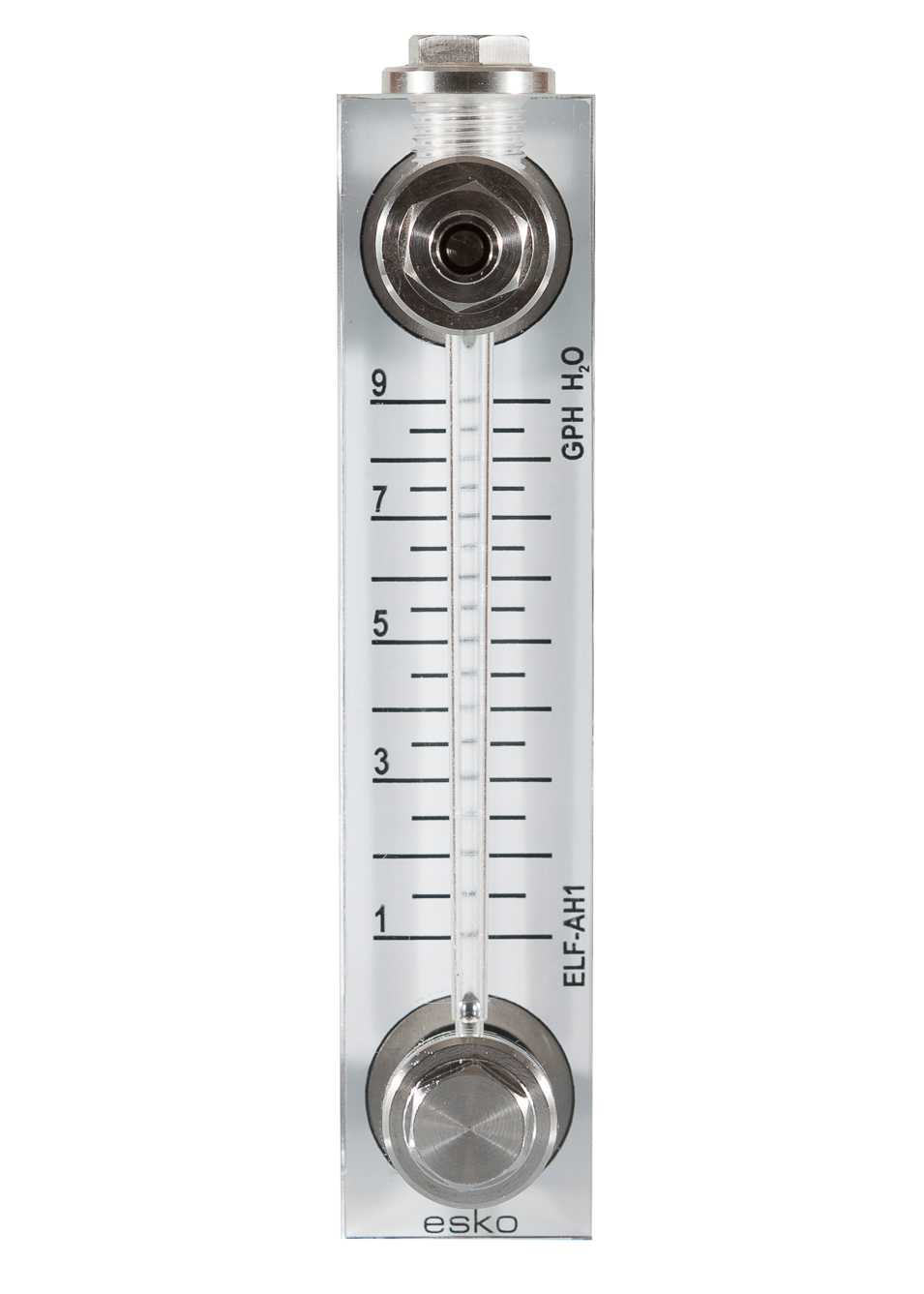

ELF Purge Flow Meter

SOLID AND RELIABLE AT A COMPETITIVE PRICE

APPLICATIONS

- Bubble tube level

- Density measurement

- Pressurized instrument enclosures

- Flow measurement

FEATURES

- Solid construction, reliable operation

- North American standard size parts

- Nitrile seals standard

- Viton® or EPDM seals optional

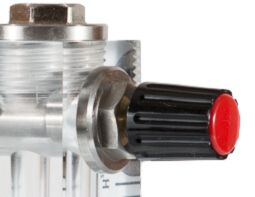

- Hand knob optional

- Freeze resistant Trogamid® or Grilamid® tube

- Excellent corrosion and heat resistance

OPTIONS

- Hand adjusting knob

- Trogamid® or Grilamid® tube

- Viton® or EPDM seals

COMPACT FLOW METER

For measurement of small flows of liquids or gases.

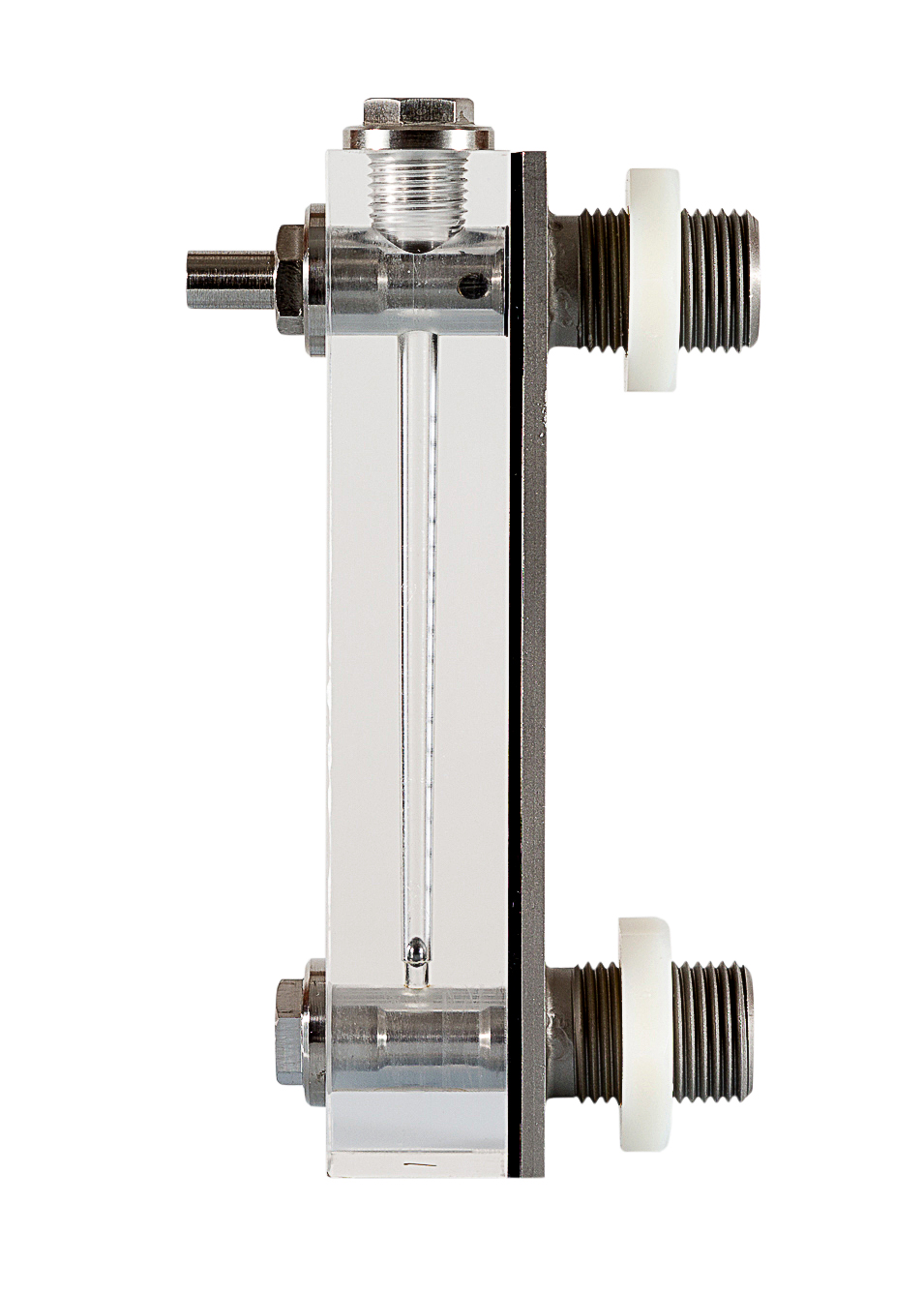

MODULAR DESIGN

Easy to change from one flow range to another by swapping out float and scale.

WHY THE ELF PURGE METER IS POPULAR

The model ELF purge meter is a compact, customizable flow meter designed for the measurement of small flows of liquids or gases. Custom materials, scales and scale markings for various flow applications are available at a competitive price. Modular design principles allow users to specify body material, flow range and media, O-ring materials and optional hand knob. ESKO offers custom scale markings and calibration for non-standard liquids and gases. The ELF is often paired with the model EFR3 constant flow regulator also designed and built by ESKO for maintaining flows in applications where supply or back pressure varies. Metallic parts on the model ELF are solid and reliable SS316 construction. The model ELF is often utilized in bubble tube level applications, density measurement, and pressurized instrument enclosures.

VARIOUS MATERIAL CHOICES

For winter operating conditions, the flow tube can be specified as freeze-resistant Trogamid. Grilamid tube material is available for corrosion resistance and heat resistance. O-ring seal materials can also be specified: Nitrile O-rings are standard, Viton O-rings tolerate high heat and EPDM is best for chemical resistance.

VALVE FEATURES AND FLOW ADJUSTMENTS

The valve can be installed on the inlet or outlet and has been designed with a back-out proof valve so that the valve spindle cannot be unscrewed. This is a safety feature that prevents an unexpected discharge of process fluid. A screwdriver adjustable flow control valve reduces the risk of inadvertent adjustment. An optional hand knob is available for easily adjusting flows to process requirements.

TECHNICAL SPECIFICATIONS

| MODEL | ELF-A | ELF-T | ELF-G |

|---|---|---|---|

| BODY MATERIAL | ACRYLIC | TROGAMID® | GRILAMID® |

| Best for | Typical applications | Corrosion and freeze resistance | Heat resistance |

| Metallic parts | SS316 | SS316 | SS316 |

| O-ring seals | Nitrile (optional Viton® or EPDM) | Nitrile (optional Viton® or EPDM) | Nitrile (optional Viton® or EPDM) |

| Maximum temperature | 167°F / 75°C @ 290 psi | 158°F / 70°C | 176°F / 80°C |

| Maximum pressure | 440 psi @ 85°F (30°C) | 440 psi @ 85°F (30°C) | 440 psi @ 85°F (30°C) |

| Connections | 1/4” NPT | 1/4” NPT | 1/4” NPT |

| Weight | 0.75 lb (340 g) | 0.6 lb (300 g) | 0.6 lb (300 g) |

BUILD OPTIONS: Body material, O-ring material, hand knob, calibration for non-standard liquids or gases

OPTIONAL ACCESSORIES: Pair any ELF meter with constant flow regulator model EFR3